Thursday, January 29, 2015

Odds And Ends

This will be a short update in the middle of the week. Just enough to cover the other steps Ill be accomplishing on the frames before final assembly. Ill be saving finally assembly for a later post. Its more than just putting parts together so I want to be able to devote more time to it.

First off, I decided to delay cutting notches for the keel, sheer, chine, and battens (dont worry, Ill explain what these are another day - suffice to say they are the lumber parts connecting the frame and giving the boat its shape lengthwise).

The location of these notches are somewhat dependent upon how the frames sit on the building form and how the wood that connects the frames bends and meets the frames. The depth of the cuts as well as the angles of the cuts are very dependent upon how the connecting lumber meets the frames. So better to wait until I have a better idea of that instead of cutting the material incorrectly.

But there are several minor steps that need to be taken with the frame parts. The inner edges of the frames will eventually be the work surface I have to kneel on when the hull is flipped over (If I havent mentioned it, the hull is built upside down initially). Since I dont want to wreck my knees, I will be slightly rounding all the inner edges of the frame parts.

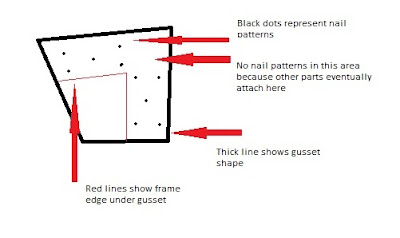

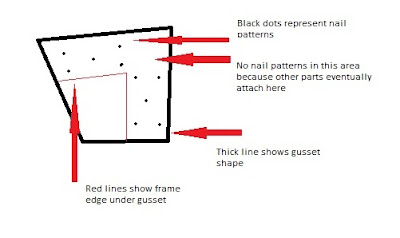

The gussets have to be nailed as well as glued when assembling the frames. To avoid splitting the wood, and to insure that I put the nails in the best locations for each part, I will be spending time laying out a nail pattern on each gusset and then drilling a small dimple at each location. The dimples will allow the nail pattern to still be visible after I final sand each part for smoothness.

Each frame part will be final sanded to remove any roughness and then re-marked with the frame number and location information. Before assembly, they will be encapsulated with epoxy resin to make them waterproof Actually, only the attachment points will be encapsulated initially because those areas will be harder to insure complete coverage with epoxy after assembly.

Each frame part will be final sanded to remove any roughness and then re-marked with the frame number and location information. Before assembly, they will be encapsulated with epoxy resin to make them waterproof Actually, only the attachment points will be encapsulated initially because those areas will be harder to insure complete coverage with epoxy after assembly.

After final assembly of the frame, any holes created in the parts during layout and manufacturing will be filled with epoxy resin and sanded smooth. The the next phase will be to encapsulate any remaining areas with epoxy.

Because I have quite a bit of frame work to accomplish, the next few updates will be a little shorter and perhaps not as often, unless I have something else I want to discuss.Well see.

In the meantime, consider this. If you feel like you want something or want to try something, but are afraid of failure, look yourself in the mirror and convince yourself that you can do whatever it is you want. Taking on a boat build is a daunting task, and I have had self doubts many times. But ultimately, I want to be able to say I accomplished this so I am going to go through with it in spite of doubts and any obstacles.

Okay, so Im off my soapbox now :)

First off, I decided to delay cutting notches for the keel, sheer, chine, and battens (dont worry, Ill explain what these are another day - suffice to say they are the lumber parts connecting the frame and giving the boat its shape lengthwise).

The location of these notches are somewhat dependent upon how the frames sit on the building form and how the wood that connects the frames bends and meets the frames. The depth of the cuts as well as the angles of the cuts are very dependent upon how the connecting lumber meets the frames. So better to wait until I have a better idea of that instead of cutting the material incorrectly.

But there are several minor steps that need to be taken with the frame parts. The inner edges of the frames will eventually be the work surface I have to kneel on when the hull is flipped over (If I havent mentioned it, the hull is built upside down initially). Since I dont want to wreck my knees, I will be slightly rounding all the inner edges of the frame parts.

The gussets have to be nailed as well as glued when assembling the frames. To avoid splitting the wood, and to insure that I put the nails in the best locations for each part, I will be spending time laying out a nail pattern on each gusset and then drilling a small dimple at each location. The dimples will allow the nail pattern to still be visible after I final sand each part for smoothness.

After final assembly of the frame, any holes created in the parts during layout and manufacturing will be filled with epoxy resin and sanded smooth. The the next phase will be to encapsulate any remaining areas with epoxy.

Because I have quite a bit of frame work to accomplish, the next few updates will be a little shorter and perhaps not as often, unless I have something else I want to discuss.Well see.

In the meantime, consider this. If you feel like you want something or want to try something, but are afraid of failure, look yourself in the mirror and convince yourself that you can do whatever it is you want. Taking on a boat build is a daunting task, and I have had self doubts many times. But ultimately, I want to be able to say I accomplished this so I am going to go through with it in spite of doubts and any obstacles.

Okay, so Im off my soapbox now :)

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment